Much to the surprise of some of the more fly-by-night startups we’ve seen come and go over the past few years, building cars is hard. Cars are extremely complex things, with many individual systems that require huge levels of engineering to be made a reality. That much became obvious on a recent visit to Brembo's engineering facilities just outside the Italian city of Bergamo.

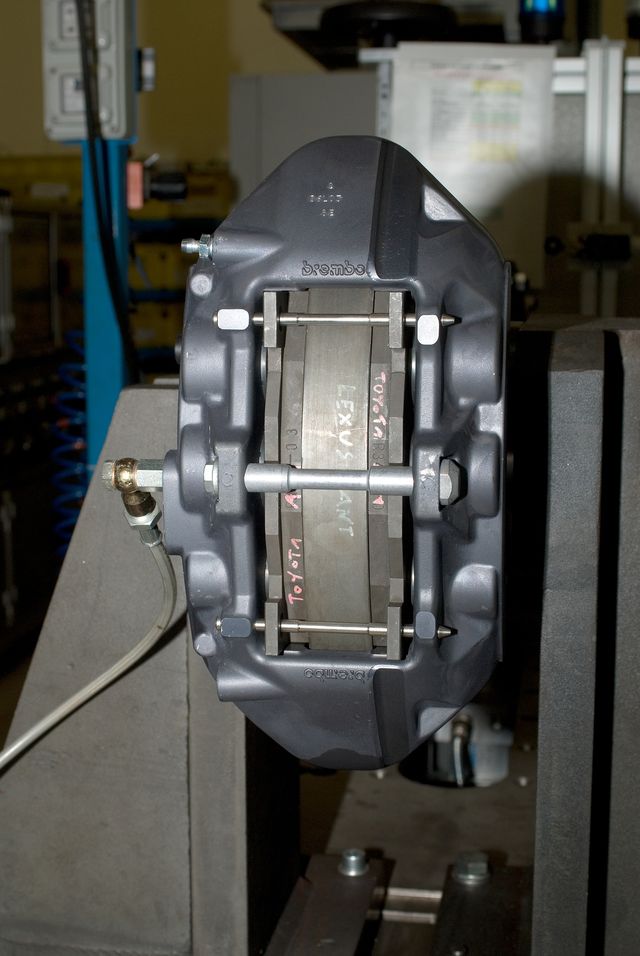

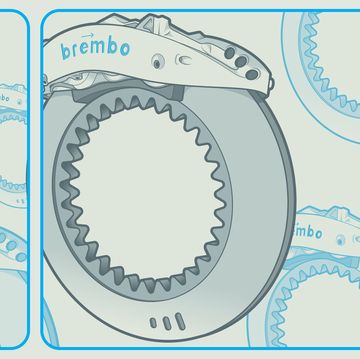

The Brembo brand hardly needs an introduction, as it's the only widely known brake supplier in the world, yet most don't know the scope of its road-car business. Brembo is one of the world's largest suppliers of original equipment (OE) performance brakes, operating factories around the world. You've seen Brembo-branded brakes offered on many high-performance cars, but the company supplies a lot more than fancy logoed calipers. If you see any car with a fixed-piston caliper—Brembo doesn't make sliding-piston calipers—there's a very good chance that most or all of the braking system came from Brembo.

Our visit revealed just how complicated life is for an automotive supplier. Developing road-car brakes, especially OE performance brakes, is no small undertaking. In some ways, it's just as complicated as making the entire car.

Brembo is unique among braking suppliers in that it makes pretty much everything in-house. Pads, discs, calipers, lines, fluids, cylinders, and in some instances, aluminum suspension components. Perhaps the best place to start in explaining why brakes are so complicated is at Brembo's material science laboratory.

Yes, there's a science lab at Brembo HQ, complete with fancy (read: expensive) electron microscopes and people walking around in white coats. It's there that the materials that make up Brembos pads, rotors, fluids, and other components are developed and tested. And the level of testing work required is extensive. For example, it has to test virtually every brake fluid available on the market to ensure it works with its components. The head of the lab, Andrea Bonfanti, told us that at one point, some American fluids were made with an aluminum alloy that destroyed caliper pistons at high-temperatures, forcing Brembo to change the material used.

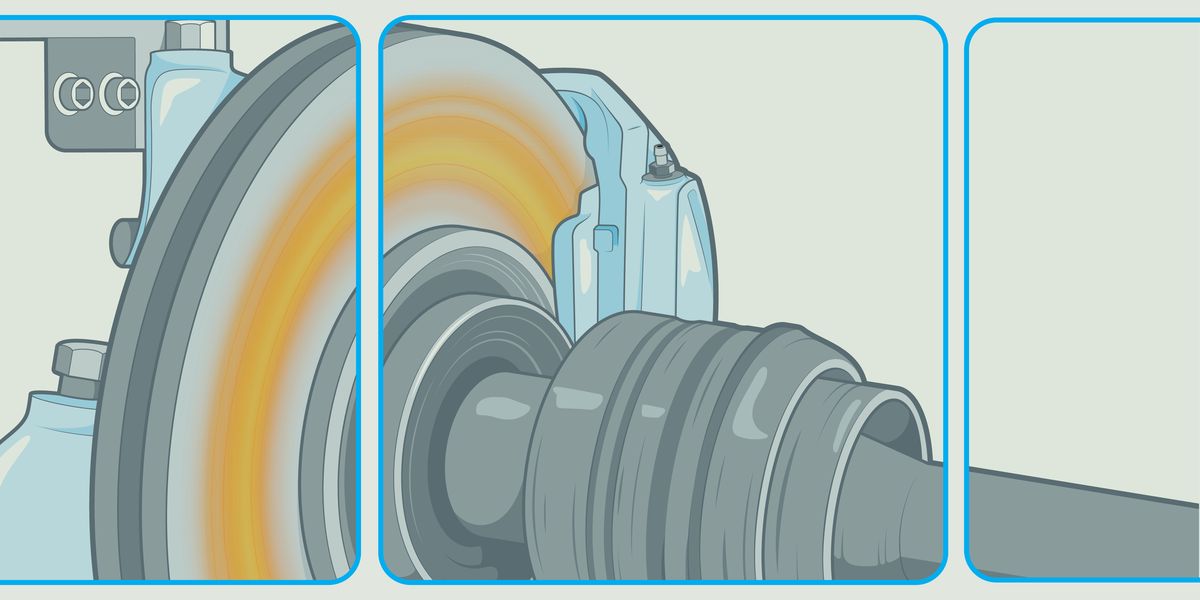

When an automaker comes to Brembo with a request to supply OE brakes, the materials researched by the lab are pressed into service. The engineers are spoiled for choice. For example, there are over 500 individual materials that can be used to make a brake pad. Once the materials are selected, prototypes are then made—pads onsite in a dedicated factory—and subjected to extensive real-world testing. Brembo wouldn't allow us to take photos, but we saw many dyno benches for testing individual brake components and entire systems in a number of different conditions. There are climatic chambers and vibration dynos that test what happens when a braking component is subject to extreme conditions.

Those climatic chambers are actually a relatively new development that allows Brembo to test components in a variety of different temperatures. "Without temperature, it's not so simple to identify issues that can change the mechanical characteristics of the material and cause damage," says Mauro Ielasi Brembo's advanced R&D department. He adds that these chambers are either the first or second in Europe.

Unfortunately, we weren't allowed to take photos of all of the many test benches, but one in particular stuck with me. Noise Vibration and Harshness (NVH) is a big concern in car development, and it's on Brembo to make sure its brakes aren't causing any problems. Automakers send Brembo entire suspension assemblies to be tested on a special dyno so that the source of any potential NVH can be found and eliminated. It seems like a ton of work, but it's the only way to know where sounds in the car are coming from.

Once all this testing work is done, real-world testing has to be done. Automakers send prototypes to Brembo directly so that their brakes can be tested on an actual car. There's a garage deep within its Curno campus where, among other things, we saw some last-gen Audi and Mercedes models presumably testing new brake developments, and a prototype mule for the new Range Rover Sport SVR. There is some testing that happens right on Brembo's campus, which sadly we weren't allowed to see, but the company also does testing at a race track just up the road, Monza. Typically, Brembo's Curno facility services European automakers, but the company has a similar, albeit smaller setup in Plymouth, Michigan where it does the same thing for American automakers.

The mind reels at all this. It's hard to process just how much work goes into making brakes for just one car. There's thousands of hours put in by engineers and scientists, using millions of dollars worth of the latest and greatest to make sure that your car will stop well no matter the conditions. (Save for normal wear and tear, obviously.)

Then you've got to build the thing. All this work is just for coming up with the product, not making it by the hundreds of thousands. Brembo only toured us around its racing plant, which operates in a very different manner than its road-car plants. But, we learned that Brembo makes basically all the braking components in-house, and it even operates its own foundries in a number of locations. That's a story for another day, however.

After trying to digest more than I'd ever thought I'd learn about brakes, I had a funny realization. This is the level of work that goes into making just one of the major systems that makes up a car. Think about what other suppliers have to do. It's easy to think that an automaker just goes to a supplier with a list of specs and then a part immediately gets put into production, but it's so much more involved than that.

It's hard to put an exact price on what it costs to engineer and manufacture a set of brakes for a road car, but there's no doubt that it's a lot. When you realize that this is the case for basically every component that goes into the car, you understand why they cost so much to develop. In other words, why building cars is so hard.

A car enthusiast since childhood, Chris Perkins is Road & Track's engineering nerd and Porsche apologist. He joined the staff in 2016 and no one has figured out a way to fire him since. He street-parks a Porsche Boxster in Brooklyn, New York, much to the horror of everyone who sees the car, not least the author himself. He also insists he's not a convertible person, despite owning three.